by Bill Grant | Oct 19, 2016 | Distilling & Bottling, Press Releases, Whisky

Elite Controls Secures Key Contract for New Macallan Distillery

LIVINGSTON, Scotland – 19 October 2016 – Elite Control Systems are delighted to announce that it has been been awarded a major contract by Scotland’s leading premium spirits company Edrington for its new distillery and visitor centre for The Macallan whisky, one of the world’s leading luxury Scotch malt whiskies.

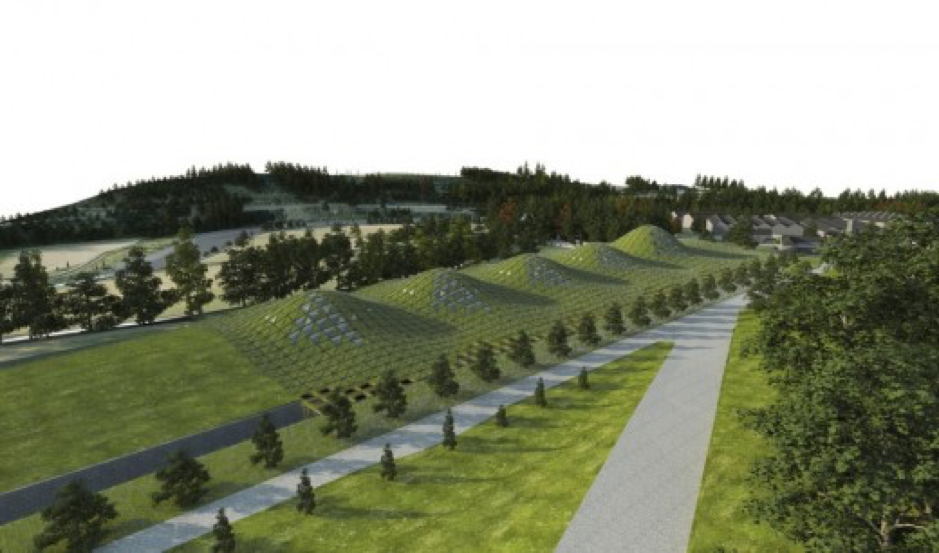

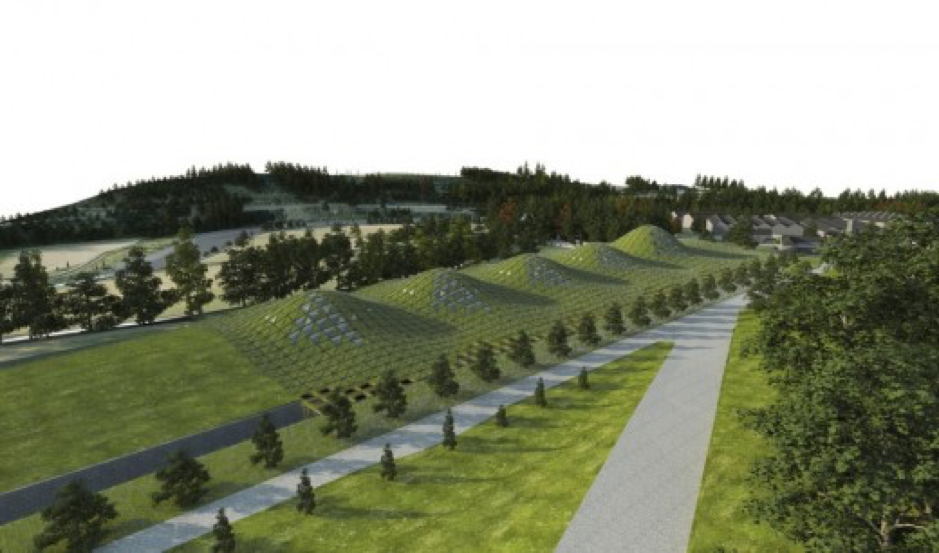

Nestled in the parklands of The Macallan Estate in Speyside, the contemporary distillery promises to be, according to Edrington, “a site of major architectural significance,” as well as a huge boost to tourism and the local economy. With architects Rogers Stirk Harbour & Partners, designers of the Millennium Dome and Pompidou Centre, commissioned to design and build it, the new facility will not only “complement the natural beauty of the area,” but be highly innovative and environmentally sound.

Edrington is relying on Elite Control Systems to write the full process software control package, and provide ongoing support services following commissioning. This combination of technology and 24-hour technical support will ensure that the automated control systems that Edrington uses to operate the new plant function properly, so that production remains on track and the visitor centre remains open to welcome thousands of visitors all year-round.

Whisky distillery project from “ground up”

For Elite Control Systems, the project represents the challenge of providing a fully operational software control system for a distillery from the “ground up.” “It’s very exciting that a brand new distillery of this size, sophistication and calibre is being built in Scotland,” said Ewan McAllister, Technical Director for Elite Control Systems.

“The fact that Elite Control Systems were selected by Edrington to provide a full software control system for the entire facility illustrates that we have earned our reputation as a recognised leader in providing control systems for the whisky industry. Clearly, Edrington are confident that we will deliver the large, complex system that this high profile facility demands. It’s an honour to have been given this opportunity to contribute to what is certain to become a testament to the quality and craftsmanship of The Macallan brand, and an outstanding experience that will attract visitors from around the world,” added McAllister.

Prior to installing the software control system on-site in Speyside, Elite will make certain that it conforms with

Edrington’s specific requirements. Initially, the control software will be simulated, tested and fully documented at Elite’s facility in Livingston to ensure a smooth commissioning period, with minimal programming required on-site.

After the facility is up and running, Elite’s dedicated Support Services division will provide around-the-clock support of the new distillery’s state-of-the-art control system. Should any hardware or network problems arise, Elite Control Systems engineers will be on standby to respond immediately to rectify the situation so that operations will resume as soon as possible. To make certain that the system functions properly, Elite will also conduct regular preventative maintenance checks, minor system modifications and training of Edrington technical staff.

Improving efficiencies for Edrington

For the past six years, Elite Control Systems has worked alongside Edrington to ensure that its process control systems operate reliably, so that production continues at optimum levels. For example, last year Elite Control Systems helped Edrington improve efficiencies at a large tank farm located at its Great Western Road facility in Glasgow, Scotland. Elite carried out an upgrade to the control system that was being used and, by doing so, eliminated the need for operators to manually route batches for blending and preparation. These functions are now carried out within the new SCADA & PLC control platform, which also allows for real-time monitoring via an internal web portal. This effectively allows management to view tank levels, transfers, final product and routes, as required.

About Elite Control Systems Limited

Founded in 1992, Elite Control Systems Limited specialises in systems integration and engineering support. It is known for helping companies within a variety of industries to use fast-moving process control, automation and information technology to achieve their business objectives.

Publications

Daily Business Group

by Bill Grant | Sep 14, 2016 | Press Releases

September 2016– We are pleased to announce the launch of our new website. Along with a new look, we have included some additional features, which we hope will provide you with an understanding of the services Elite Controls offers and instil you with confidence that we can deliver the best possible service for your company.

What can you expect……

Homepage- We wanted to give the homepage a different look, including a new homepage banner, and what better way than to show some of our own staff and engineers!

Navigation- We have created the website in such a way that it allows easy navigation, with access to our services via the menu bar or thumbnails on the homepage.

Testimonials- We have also added a separate page on testimonials provided by both current and previous clients. We believe it is important to evidence some of the work we have carried our for clients, and we hope to keep adding to this.

Latest News- Keep up to date with the latest news on Elite Control Systems. We have exciting projects coming up, so don’t miss out on being the first to find out!

Social Networking– In addition to our news section, you can also find social networking links throughout the website, so feel free to follow us and find out what we are up to!

About Elite….

Elite Control Systems is a Scottish based Systems Integrator, and provides engineering support services including software and system design, across a range of Industries. Elite was the first automation system integration company to obtain the ISO9001:2000 tickIT certification for design, management and maintenance of application software. Elite are also the first systems integrator, worldwide to be certified to carry out Safety System and Safety Consultancy by one of the world’s leading safety equipment manufacturers.

by Bill Grant | Sep 8, 2016 | Press Releases, Uncategorized

Tina Campbell has been appointed Marketing Coordinator by systems integrator Elite Control Systems which provides various engineering support services to customers in the UK and globally.

Tina Campbell has been appointed Marketing Coordinator by systems integrator Elite Control Systems which provides various engineering support services to customers in the UK and globally.

In her new role, Tina is responsible for planning and executing both online and offline marketing strategies and campaigns. More specifically, she manages media relations, contributes to website and social media content, carries out web analytics, produces promotional films, and conducts market and product related research.

To further strengthen the company’s exceptional reputation for helping customers to operate efficiently, she is committed to raising awareness of their services and products around the world. To achieve this, Tina relies heavily upon digital marketing, as well as more traditional methods.

“When used effectively, the power of digital marketing is phenomenal. Elite Control Systems provides engineering solutions to companies that operate in a variety of industries. In addition to its strong portfolio in the whisky sector of the bottling and distilling industry, the company serves customers in the oil and gas, food and beverage, and manufacturing industries. By communicating regularly – and instantaneously – with our customers and target markets, I am confident that word of the company’s offerings will spread rapidly, allowing other companies to find out about the great benefits they can achieve with Elite Control Systems,” said Campbell.

“We have invested many years developing technologically advanced process control systems, and feel that the time is right to accelerate how we promote them to the marketplace,” said Brian Sneddon, General Manager of Elite Control Systems. “Tina is a passionate, dedicated marketing professional with great drive and experience. We are certain that she will help us to identify opportunities and improve communication with our key markets. We look forward to working with her and welcome her to the team.”

Prior to her appointment as Marketing Coordinator, Tina gained valuable marketing, public relations and sales experience while working for Optical Express, STV Group and ticket sales company TicketSoup.com in Glasgow. Originally from Fort William, Scotland, Tina holds a BA (Hons) Degree (2:1) in Marketing from Glasgow Caledonian University, and is studying for a Professional Certificate in Digital Marketing from the University of Aberdeen.

Other Publications

SBNN

About Elite Control Systems Limited

Founded in 1992, Elite Control Systems Limited specialises in systems integration. It is known for helping companies within a variety of industries to use fast-moving process control, automation and information technology to achieve their business objectives.

by Bill Grant | Aug 25, 2016 | Press Releases

January 20, 2016 – Elite Control Systems now offers Vibration Monitoring and Profibus Network health checks predictive maintenances services.

“By providing customers with the option to have their systems monitored for vibration and put through regular Profibus Network health checks, we’re helping them take preventive measures to predict and detect potential defects, long before they have the chance to develop into a real problem,” said Angus McCarter, Field Sales Engineer for Elite Control Systems. “When combined with elements of our full range of support services, our customers know that they are taking every precaution to ensure that their systems operate smoothly, with minimal disruption.”

“Because engineering support is such an essential part of any automated manufacturing system, we decided to establish a dedicated Support Services division, when most systems integrators were offering it as an add-on service or afterthought,” said Brian Sneddon, General Manager of Elite Control Systems. “In contrast, our engineering team is fully briefed on every customer’s needs, and is on-hand around the clock. So, whether a customer has a comprehensive 24/7 support plan in place or is on an ad hoc call-out basis, Elite engineers are ready to respond immediately in the event of a breakdown, so that production is up and running as quickly as possible.”

The addition of Vibration Monitoring and Profibus network health checks to its Support Services portfolio is particularly meaningful because companies can now derive comprehensive support, without going to the expense of creating extensive support teams internally. Companies can access Elite’s engineering expertise, as well as that of its partners who are some of the world’s leading automation and process control manufacturers.

“Predictive care has always been synonymous with quality system maintenance. It makes economic sense, because you’re making a minimal investment now to avert a more expensive problem such as a shutdown in production or major equipment failure” said Ewan McAllister, Technical Director of Elite Control Systems. “Plus, by customising every client’s support contract to their individual needs, they only pay for what they need so it’s financially viable. it’s a win-win situation for all concerned.”

In addition to the new predictive maintenance services, Elite offers breakdown support for PLC, SCADA, IT systems and network infrastructure, such as integrity testing. Its Support Services engineers also conduct system audits, health checks, minor modifications, and on–the-job training for clients’ employees.

About Elite Control Systems Limited

Founded in 1992, Elite Control Systems Limited is a highly regarded, innovative company that specialises in systems integration. It is known for helping companies within a variety of industries to use fast-moving process control, automation and information technology to achieve their business objectives.

Publications: Automation.com

by Bill Grant | Aug 25, 2016 | Press Releases

The automation value proposition for today’s manufacturer is a healthy one, with enterprises targeting more connected plants and tighter supply chain integration. Global spirits producer Edrington is no different.

The company began expanding beyond its Scotch whisky roots in 2008 when it acquired a leading producer of rum. Then in 2010, the Cutty Sark brand and numerous vodka spirits were added to the portfolio. The exponential growth in spirit offerings has led to high-volume production challenges at its Great Western Road facility in Glasgow, Scotland, and also a desire for better efficiencies.

To find that efficiency, the company upgraded its SCADA platform to better manage its large tank farm that holds spirits ready for final mixing.

Edrington enlisted Elite Control Systems, which provides integration services for numerous industries, to modernize its SCADA control platform at the bottling plant. The objective was to redesign the company’s liquid handling system that uses Siemens hardware and software to reduce operator time on routing batches for blending and preparation.

The new platform includes four programmable logic controllers (PLCs) and safety controllers, and supports all whisky operations in the four main areas of the plant: two whisky supply sections, a tank farm and vat room. Each of those four blending areas has a dedicated PLC that controls valves, motors and pumps.

“Different routes and recipes are generated by master blenders for each spirit, which means thousands of possible routing combinations from many different tanks,” says Juan Carlos DiBella, engineering manager at Elite Control Systems. “However, the main concern for the system is to transfer the spirits safely and accurately.”

Operators rely on the liquid handling system to mix different spirits, select batch recipes, and implement the right amount of filtering, caramel additions or demineralized water for each vessel. This process includes the ability to measure the correct color and strength for different batches.

Two whisky supply areas—blend areas 1 and 2—contain products from casks and tankers that are the most valuable products at the plant, according to Elite Controls Systems. The tank farm section holds high-demand spirits, mostly for The Famous Grouse whisky.

Each tank throughout the Great Western Road plant has temperature and level sensors that communicate to each PLC via Profibus. The plant uses 12 WinCC PC clients to monitor and control these processes.

One reason for the SCADA plant upgrade was to remove manual routing from the process. Before the upgrade, routing product to a production line used to mean manually adjusting a series of valves and pumps that could require up to several days.

“Operators can now select a certain amount of product from multiple vessels and the SCADA platform, via the SQL database, will select the proper valves for that route,” DiBella says. “The entire routing can be done in one execution, with operators simply selecting a source, destination and the amount of spirit to transfer. Operators can execute more than 5,000 types of transfers.”

Elite Controls also provides ongoing support for Edrington and assists in the creation of new routes for operators. “If we have to create a new route, we do that only in the database,” DiBella says. “We don’t have to touch the SCADA platform or the PLC.”

Investment benefits

In addition to automated routing complexities, the SCADA investment has led to better enterprise reporting and thorough safety monitoring for the entire process.

Edrington produces highly flammable spirits, so valve control is closely monitored with low-power solenoid valves to meet European Union (EU) explosion prevention standards. “If the system detects a level change in a vessel due to a valve being open or failing, the system highlights it and stops the process, avoiding any loss of product or any contamination,” DiBella says.

With the exponential growth in products, enterprise monitoring is vital. This new platform allows for real-time monitoring via an internal web portal so management can also view tank levels, transfers, final product and routes.

The SCADA upgrade was the first component of the plant modernization project at the Great Western Road facility. Other components include optimization in enterprise reporting and overall processes.

Publications:

By Grant Gerke , Automation World Contributing Writer, on February 16, 2016

by Bill Grant | Aug 25, 2016 | Press Releases

Elite Controls has developed an “intelligent” routing system that, it says, represents a dramatic advance in production speed and efficiency for the beverage and bottling industry. Scottish whisky distilleries are already using the system to transfer essential ingredients from one point to another during the blending and bottling process.

One of the main advantages of the software system is that it automates the setting of equipment such as valves and pumps, that has traditionally been set manually in a process that can take hours, or even days. The new system allows an operator to make these adjustments in seconds from a computer.

“Routing product to a production line used to mean manually adjusting a series of valves and pumps, which, in some cases, could take up to several days,” explains Elite Control Systems’ technical director, Ewan McAllister. “Because our new routing system is capable of creating upwards of 25,000 routing configurations, it’s just a matter of selecting the source and destinations for a route.

“Say you want to transfer 10,000 litres of a specific product from blending tanks to the production lines,” he continues. “The operator simply selects the source and the destination on the routing system, and the route is set up immediately. The fact that the system is intelligent means that it ‘knows’ when a particular route is busy and will alert the operator of this, allowing an alternative route to be selected or the transfer to be queued until the route becomes available. This means that the tank farm can run at full capacity, dramatically increasing production.”

The system allows routes to be added or modified without any changes to the PLC logic.

It is claimed to do much more than setting up transfer routes at the flick of a switch. Because blending of ingredients is critical to drinks producers, the system can control other areas of the production process, such as blending. It is programmed to measure volumes of ingredients to be transferred into the vessels, and how long they should stay in the vessel before continuing with the next part of the process. It can also monitor the temperature, volume, alcohol strength and colour of an ingredient as moves through the blending process.

After the transfer process is completed, the system can provide production data, such as where the input ingredients came from, when they arrived, and even the vehicle that transported the ingredients. This data is stored for future use.

The system guides operators safely and accurately through every step of a process. The program uses object-oriented programming which allows large systems to be broken down into simple-to-manage functional modules or “objects.” The routing information is handled by an SQL routing database.

Although the system is being used primarily for tank farm control in the distilling and bottling sectors at present, Elite Control Systems has also installed the system in a petrochemical plant.

Other Publications: