by Sarah Grant | Jun 10, 2025 | Announcement, Blog Post, Feature Articles

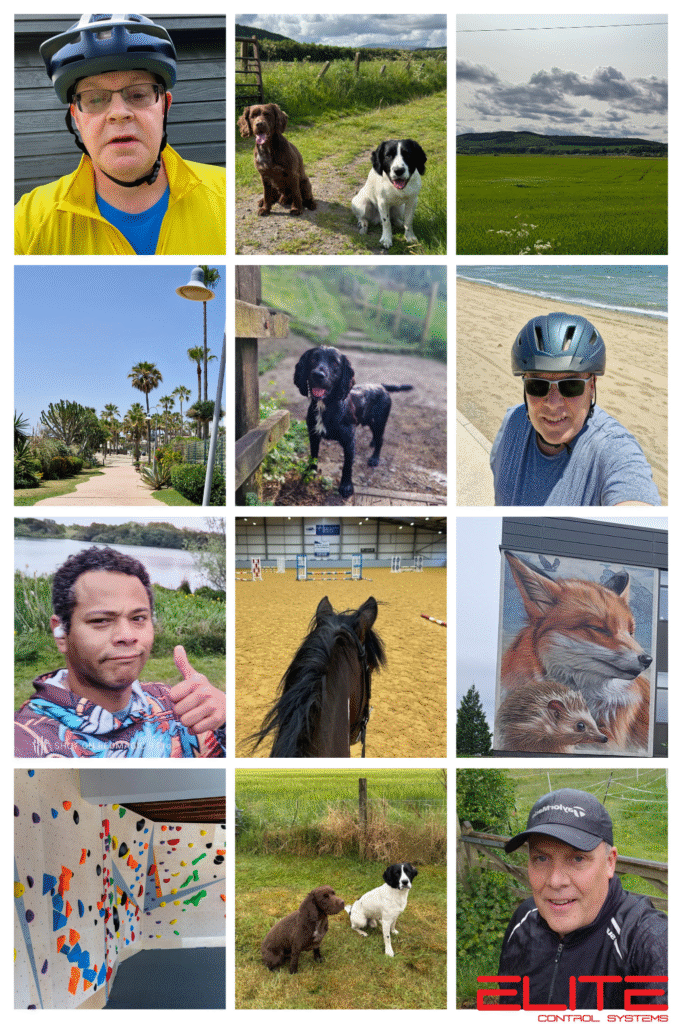

We’re officially halfway through the Elite Fitness Challenge, and the competition is tighter than ever. With hundreds of hours of activity, thousands of miles logged, and plenty of sweat (and probably some sore legs), the energy across all teams is electric.

Here’s your Week-by-Week Recap of the action so far 👇

🏁 Week 1: Sweat Equity Delivered

The challenge kicked off strong with incredible enthusiasm across the board.

Key Stats:

- 🕒 6,500+ active minutes

- 🛣️ 354 miles covered

- 🏆 1,420 challenge points earned

Team Rankings:

1️⃣ Gym & Tonic – Leading in both points and distance

2️⃣ Over Runners – Most sessions logged; true endurance champs

3️⃣ Pace Invaders – Dominating the mileage game

4️⃣ Heavy Duty Juggernauts – Creative contenders with high energy

Top Activities:

- 🚶♂️ Walking & Hiking: Most popular across all teams

- 🚴 Cycling: High-point returns for high-mileage effort

- 🤾 Team Sports, 🏋️ Gym Sessions & 💃 Fitness Classes: Diverse and consistent contributors

⛰️ Week 2: Moving Mountains (Literally)

The challenge escalated with massive gains and growing intensity.

Cumulative Totals:

- ⏱️ 12,800+ minutes of activity (that’s 8.9 days of non-stop movement!)

- 🛣️ 670+ miles logged

- 🏋️♀️ 244 total sessions recorded

- 💥 2,926 points earned – including 60 bonus points for effort, spirit, and consistency

Team Standings:

🥇 Pace Invaders – Climbing the ranks with strategy and balance

🥈 Gym & Tonic – Logging major mileage with dependable results

🥉 Heavy Duty Juggernauts – Momentum building with all-round consistency

4️⃣ Over Runners – Most activities, now eyeing higher-scoring moves

Activity Trends:

- 🚶 Walking still reigns supreme

- 🚴 Cycling & 🤾 Team Sports are gaining ground

- 🧘 Fitness Classes & 🏋️ Weight Training showing strong, steady growth

- 🏃 Running & 🏊 Swimming remain under-utilised – a great area to boost in Week 4!

🔥 Week 3: The Midpoint Push

Midway through the challenge and the stats are next-level:

Group Totals So Far:

- 📝 374 activities logged

- ⏱ 340+ hours of movement

- 🛣️ 1,017 miles travelled (that’s Edinburgh to Paris, with time for sightseeing!)

- 🏅 4,560 total points earned

Leaderboard Update:

🥇 Pace Invaders – Narrow lead thanks to smart strategy

🥈 Over Runners – Highest total time, grinding it out with determination

🥉 Heavy Duty Juggernauts – Strong and steady

4️⃣ Gym & Tonic – Still in the mix, and capable of a comeback

Standout Activities:

- 🚶 Walking/Hiking: Leading with 2,205 points and 556 miles

- 🚴 Cycling: Gaining speed with 817 points

- 🤾 Team Sports: Massive group sessions driving momentum

- 🧘 Fitness Classes & 🏋️ Gym Workouts: Delivering consistent, repeatable gains

- 🏃 Running & 🏊 Swimming: Still with room to grow

💡 Key Takeaways So Far

- Team strategies are evolving – and every session logged now makes a bigger impact

- Walking is the foundation, but cycling and team sports are climbing fast

- Individual efforts are phenomenal – and team spirit is off the charts

- With three weeks down and one to go, it’s anyone’s game

With three weeks down and three to go, there’s still everything to play for: This is more than just a fitness challenge – it’s a community moving towards better health, stronger habits, and a little friendly rivalry.

Let’s crush Week 4 and beyond!

by Sarah Grant | May 22, 2025 | Announcement, Blog Post, Feature Articles

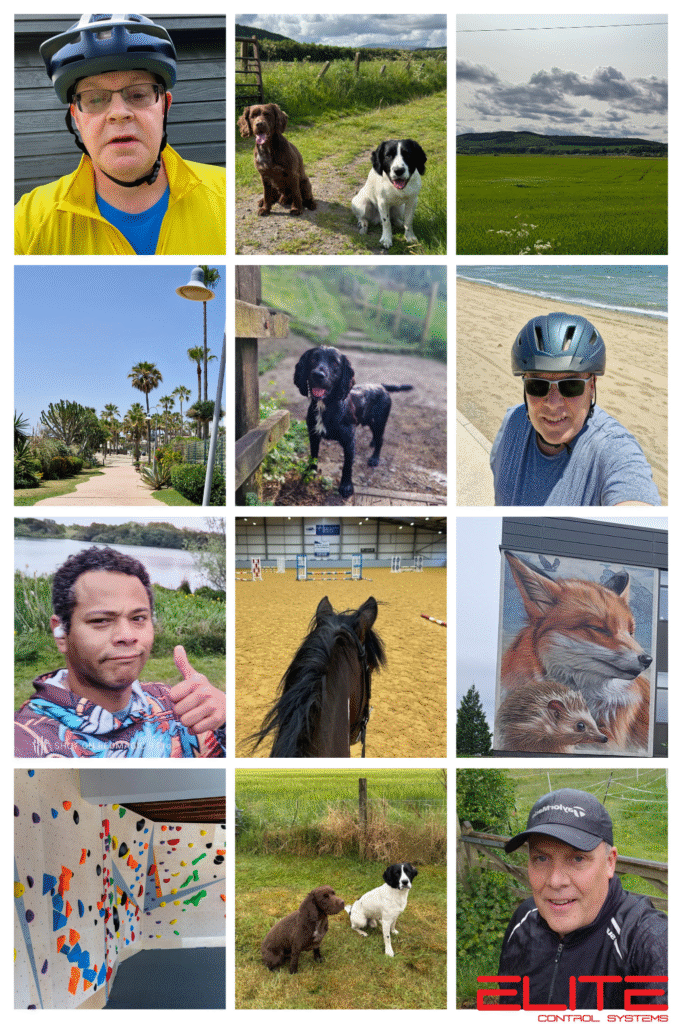

We’re mixing things up for 2025! This year, instead of our usual Cycling Challenge, we’ve launched something new and exciting — the Elite 6-Week Fitness Challenge, designed exclusively for our amazing team.

Whether you’re into walking, cycling, swimming, gym sessions, or team sports, this challenge is all about getting active in a way that works for you. It’s open to everyone, no matter your fitness level or where you are on your personal wellness journey.

🏃♀️🚴♂️🏊♂️🏋️♀️⚽

We’re already a few days in, and the energy is incredible! Teams are stepping up, clocking in activities, and racking up points — it’s shaping up to be a tight race and the competitive spirit is alive and well!

This is your chance to move more, support your teammates, and have a bit of fun along the way. We’ll be sharing updates throughout the challenge and announcing the winning team at the end of the 6 weeks.

Let’s make this summer one to remember — Summer Fit Starts Now, Team Elite!

by Sarah Grant | Apr 25, 2025 | Announcement, Blog Post, Feature Articles

We are thrilled to announce that Elite Controls Systems has been reaccredited with SafeContractor. This achievement underscores or steadfast commitment to not only top-quality expertise, but a tangible commitment to safety and compliance.

At Elite Controls, our reaccreditation means you can continue to expect reliable industry-leading services that prioritise both safety and quality in every project. Our dedicated Engineering team ensures that all our client’s receive the best in Engineering controls and automation services.

To all our valued customers, thank you again for trusting us with your business!

To Learn More about SafeContractor, please visit their website here.

by Sarah Grant | Apr 8, 2025 | Announcement, Blog Post, Feature Articles

We’re proud to announce that Elite has been re-certified by Achilles and is fully registered as a Silver Level Supplier on the Achilles Global Energy Community! This recognition reinforces our commitment to excellence, reliability, and the highest industry standards.

A huge thank you to our dedicated team, whose hard work and commitment have ensured we continue to meet and exceed expectations and all of the team are looking forward to continuing to provide top-quality service and maintaining and building upon our strong reputation within the industry.

by Sarah Grant | Mar 24, 2025 | Announcement, Blog Post, Feature Articles

The team at Elite Control Systems was thrilled to be a supporter of the CeeD Award Night, which took place earlier this month an inspiring event that celebrates innovation, excellence, and the hard work of businesses making a real impact. This year, we had the pleasure of attending alongside David Strachan from Terumo Aortic, enjoying delicious food, great company, and witnessing an award ceremony that showcased many excellent ideas coming to life.

The night was filled with excitement as well-deserved winners were recognised for their remarkable achievements. It’s always uplifting to see creative and ambitious ideas take shape, and we were proud to be part of such a special evening. We were particularly pleased to see CeeD themselves recognised receiving a well-deserved award for their contribution and this was graciously accepted by their Managing Director Joe Pacitti.

At Elite Control Systems, we value innovation and the strength of being part of a creative community. We are committed to continuous growth and are excited to be a part of the dynamic and forward-thinking network of peers and professionals that the CeeD Award Night brings together. We are already looking forward to next year’s event, and we hope to see Elite Control Systems once again as a nominee, ready to showcase our own teams dedication to innovation and excellence.

Congratulations to all the winners and thank you to everyone who made this night such a success. We look forward to next year’s celebration of creativity, teamwork, and achievement.

#EliteControlsSystems #CeeD #CeeDIndustryAwards2025 #CeeDAwards #Innovation #TermunoAortic #CelebratingSuccess #InnovationInBusiness #ProudSupporters

by Sarah Grant | Jan 24, 2025 | Announcement, Blog Post, Feature Articles

Our team kicked off 2025 with an exciting and engaging training day on the Aveva platforms, using the innovative Innovation Labs training materials, all delivered by the experts at Solutions PT!

The boardroom was buzzing with energy as our team dove into hands-on, interactive labs included a variety of engaging sessions, from designing modern architectures using MQTT Sparkplug B and OPC UA, to exploring innovation in HMI and SCADA systems. We also delved into the effective use of plant data through Historian and techniques for reporting to stakeholders. Each session was packed with valuable insights and practical knowledge that will help drive success in our projects this year.

And of course, no training session is complete without pizza – which was a major hit at lunch!

A huge thank you to Solutions PT for putting together such a valuable and enjoyable experience for the Elite team. We’re looking forward to applying what we’ve learning and continuing to innovate this year!

by Sarah Grant | Dec 16, 2024 | Announcement, Blog Post, Feature Articles

As the festive season approaches our team extends warm wishes to everyone for the upcoming festivities.

Should you need our help over this period our office opening hours are:

- The Pre-Engineering/Sales Office will be closed from the 20th of December 2024 and reopens on the 6th of January 2025

- Please note that Our Engineering department will be closed from the 20th of December 2024 and reopens on the 6th of January 2025

- Support – Customers with an Elite support contract you continue to access the service as normal by using the dedicated support telephone number. If you require remote support, please contact your dedicated support line number as normal and one of the team will assist.

For any customers who do not have a support contract in place but have concerns over cover for this period then please contact us as soon as possible to discuss options and where we may be able to assist and provide cover including the setup of dedicated remote access support.

Wishing you all the compliments of the season!